menu

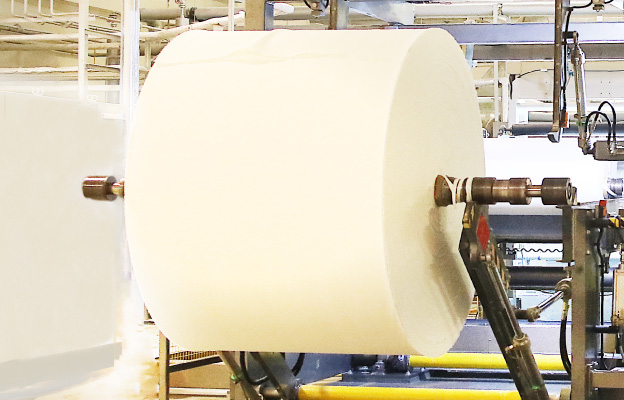

Nonwoven Fabric

Handled

Kinseiʼs Nonwoven Fabrics

Four different manufacturing processes enable us to offer a variety of nonwoven fabrics.

We primarily manufacture articles as they are ordered so that we can provide only the highest quality products tailored to meet customer requirements.

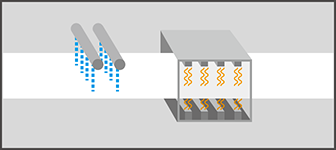

Thermal bond

Bonds fiber webs using

a thermoplastic fiber

that melts when heated.

a thermoplastic fiber

that melts when heated.

■Bonding : Thermoplastic fibers

■Characteristics : Safe and hygienic due to being bonded with heat.

Fabrics made using this process can be laminated to

other nonwoven fabrics.■Mass per unit area : 15g/m2 - 50g/m2

■Maximum width : 2,050mm

■Example uses : Diapers, sanitary product surface materials, filters

■Characteristics : Safe and hygienic due to being bonded with heat.

Fabrics made using this process can be laminated to

other nonwoven fabrics.■Mass per unit area : 15g/m2 - 50g/m2

■Maximum width : 2,050mm

■Example uses : Diapers, sanitary product surface materials, filters

■Bonding : Thermoplastic fibers■Characteristics : Safe and hygienic due to being bonded with heat. Fabrics made using this process can be laminated to other nonwoven fabrics.■Mass per unit area : 15g/m2 - 50g/m2■Maximum width : 2,050mm■Example uses : Diapers, sanitary product surface materials, filters

Airthrough

Heat calendar

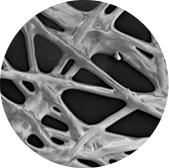

Enlarged image

Chemical bond

Bonds fiber webs using

a chemical binder.

a chemical binder.

■Bonding : Saturation

■Characteristics : Texture can be adjusted by selecting an appropriate binder.

Fabrics made using this process can be laminated to other nonwoven fabrics.■Mass per unit area : 16g/m2 - 100g/m2

■Maximum width : 2,200mm

■Example uses : Water-absorbing sheets, interfacing, backing, filters

■Characteristics : Texture can be adjusted by selecting an appropriate binder.

Fabrics made using this process can be laminated to other nonwoven fabrics.■Mass per unit area : 16g/m2 - 100g/m2

■Maximum width : 2,200mm

■Example uses : Water-absorbing sheets, interfacing, backing, filters

■Bonding : Saturation■Characteristics : Texture can be adjusted by selecting an appropriate binder. Fabrics made using this process can be laminated to other nonwoven fabrics.■Mass per unit area : 16g/m2 - 100g/m2■Maximum width : 2,200mm■Example uses : Water-absorbing sheets, interfacing, backing, filters

Enlarged image

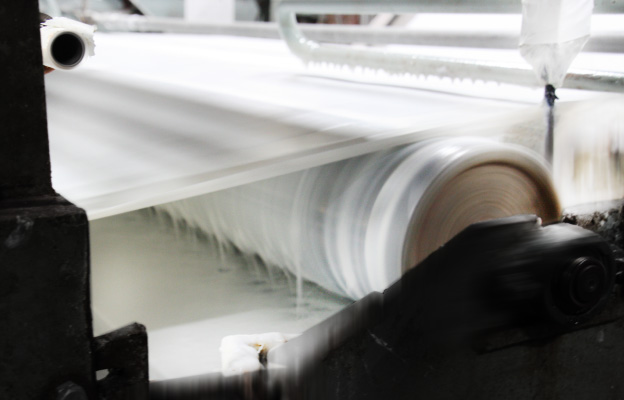

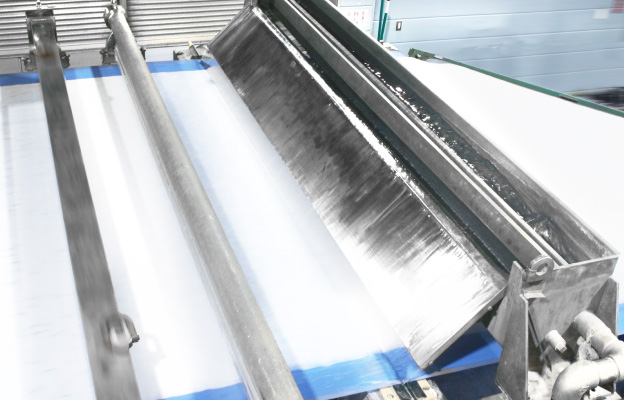

Spunlace

Entangles fiber webs

using high pressure

water jets.

using high pressure

water jets.

■Bonding : High pressure water

■Characteristics : Does not use an adhesive allowing the special characteristics

of fibers to be brought out.■Mass per unit area : 25g/m2 - 70g/m2

■Maximum width : 2,050mm

■Example uses : Wipes, food, medical

■Characteristics : Does not use an adhesive allowing the special characteristics

of fibers to be brought out.■Mass per unit area : 25g/m2 - 70g/m2

■Maximum width : 2,050mm

■Example uses : Wipes, food, medical

■Bonding : High pressure water■Characteristics : Does not use an adhesive allowing the special characteristics of fibers to be brought out.■Mass per unit area : 25g/m2 - 70g/m2■Maximum width : 2,050mm■Example uses : Wipes, food, medical

Enlarged image

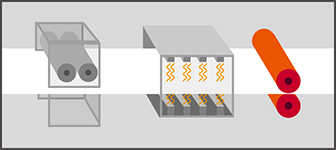

Airlaid

Uses heat to bond sheets

made by dispersing thermoplastic

and pulp fibers in an air stream

onto a screen.

made by dispersing thermoplastic

and pulp fibers in an air stream

onto a screen.

Uses heat to bond sheets made by dispersing thermoplastic and pulp fibers in an air stream onto a screen.

■Bonding : Thermoplastic fibers

■Characteristics : Bulk and high absorbency using pulp.

Fabrics made using this process can be laminated to other nonwoven fabrics.■Mass per unit area : 16g/m2 - 650g/m2

■Maximum width : 1,300mm

■Example uses : Absorbent materials, filters

■Characteristics : Bulk and high absorbency using pulp.

Fabrics made using this process can be laminated to other nonwoven fabrics.■Mass per unit area : 16g/m2 - 650g/m2

■Maximum width : 1,300mm

■Example uses : Absorbent materials, filters

■Bonding : Thermoplastic fibers■Characteristics : Bulk and high absorbency using pulp. Fabrics made using this process can be laminated to other nonwoven fabrics.■Mass per unit area : 16g/m2 - 650g/m2■Maximum width : 1,300mm■Example uses : Absorbent materials, filters

Enlarged image

Japanese

Japanese